SprutCAM X

Included features:

- Commercial License for 2.5- and 3-axis milling

- Index 5-axis (3+2) machining

- Adaptive SC high speed strategy

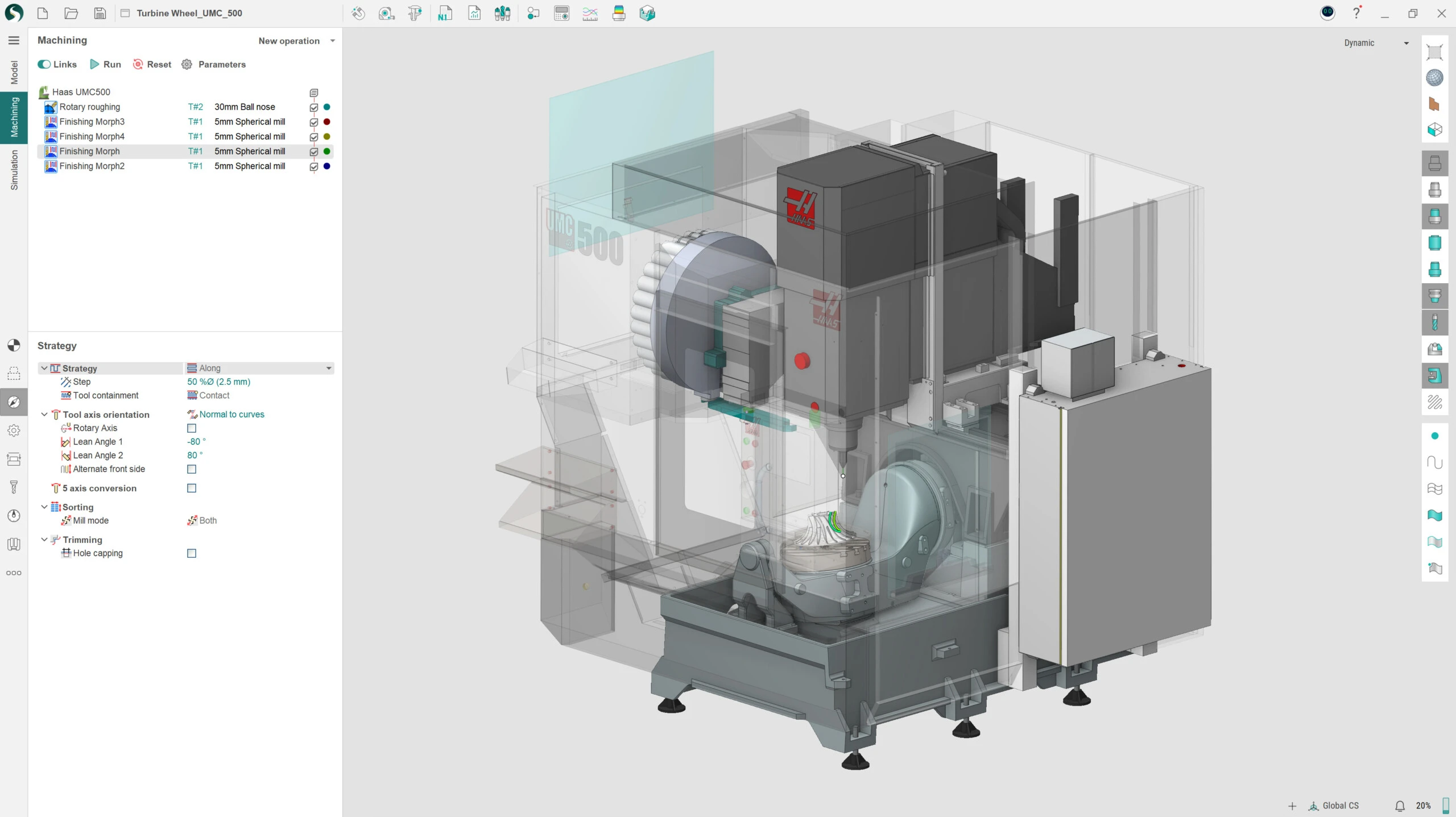

- Simulation of subtractive and additive processes, support for G-code verification

- Zero code digital twin builder: MachineMaker

- Postprocessor generator

- Access to fundamental online video course

Options

Product Highlights

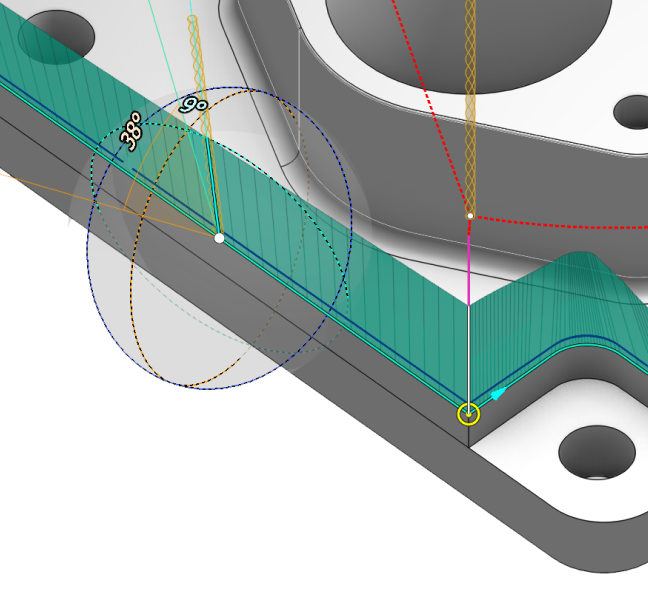

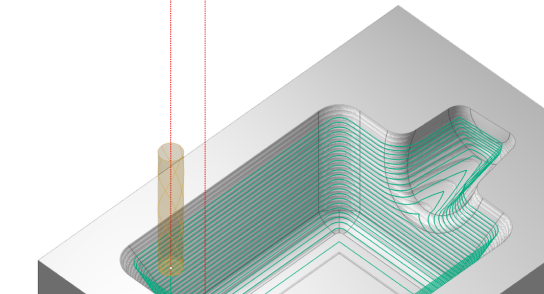

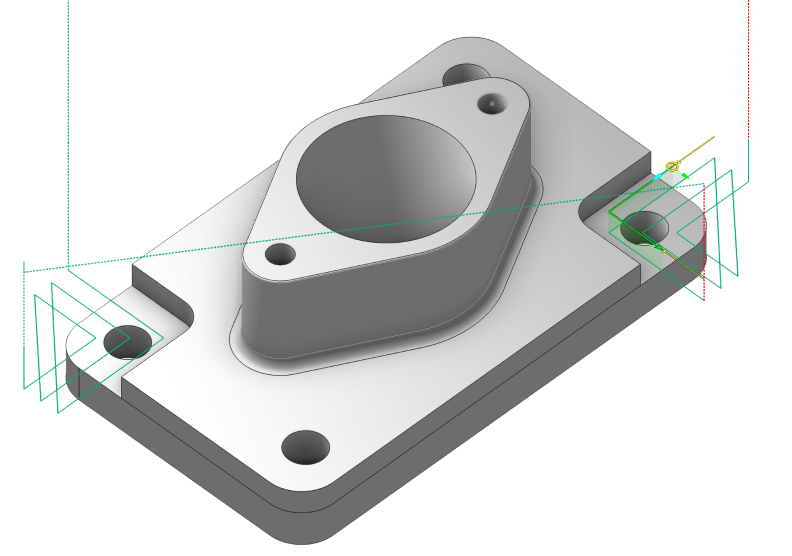

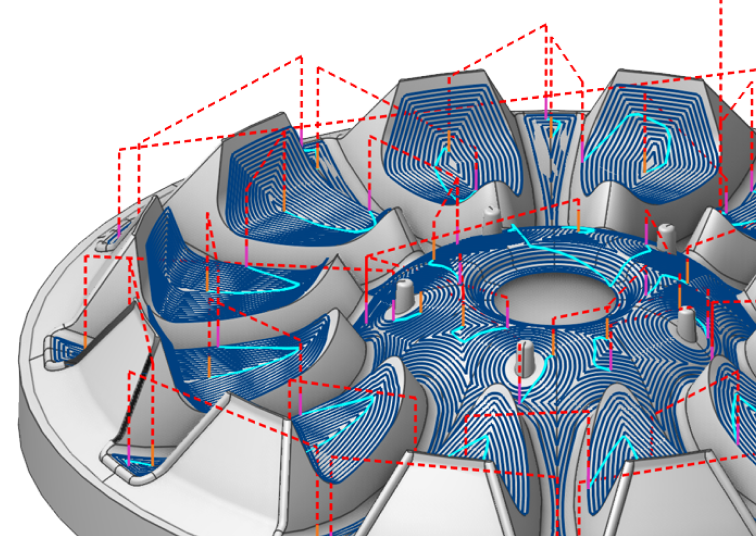

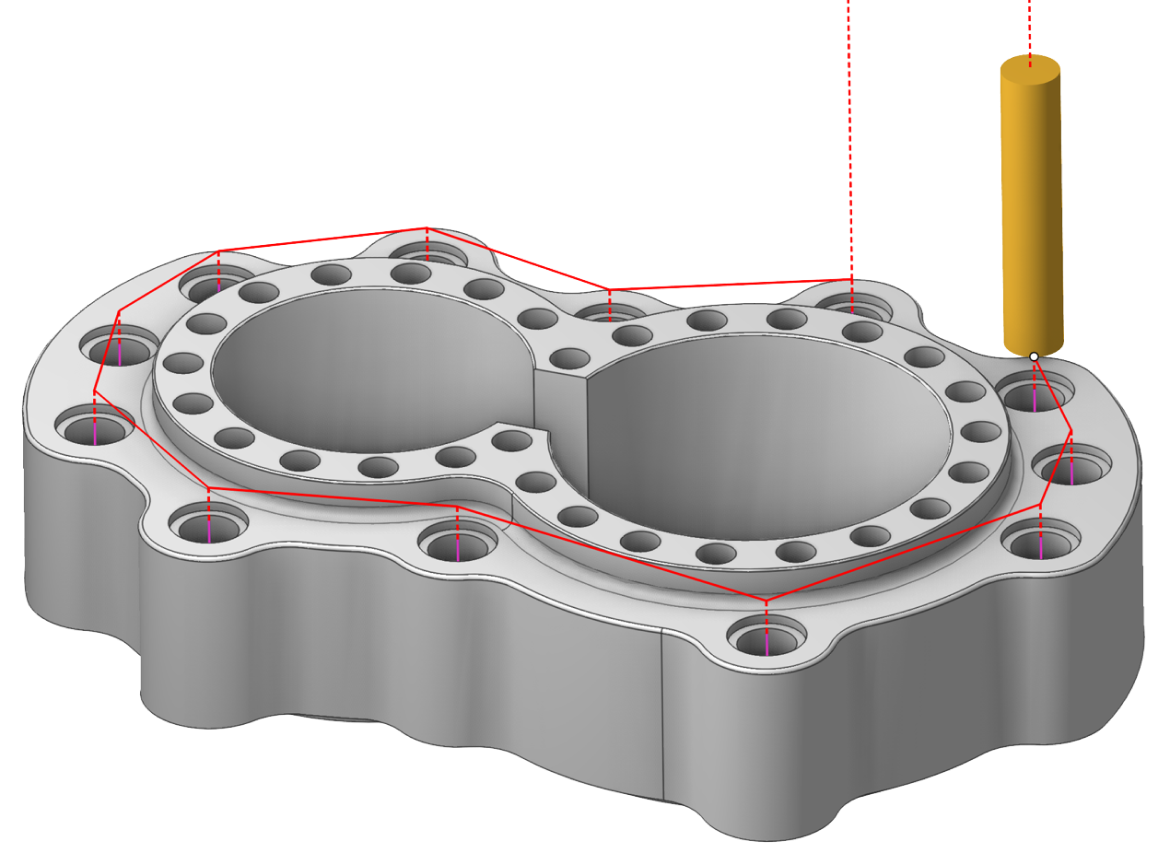

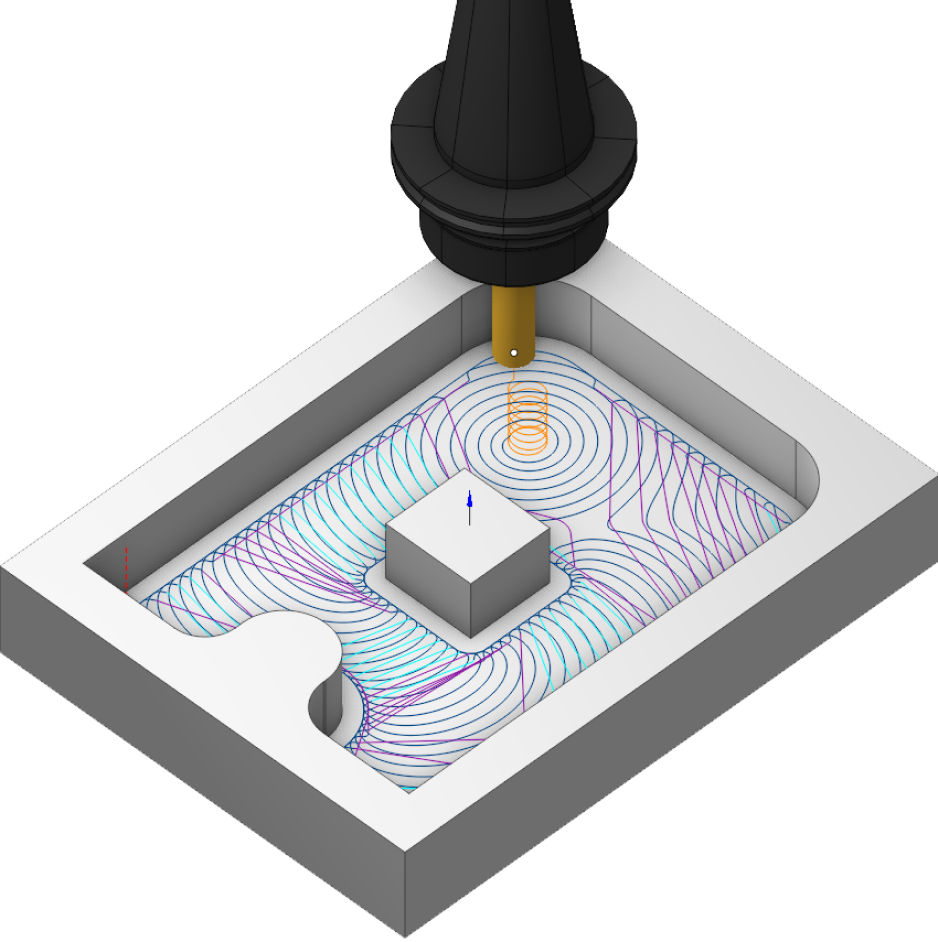

A wide range of machining strategies from 2D to 5D

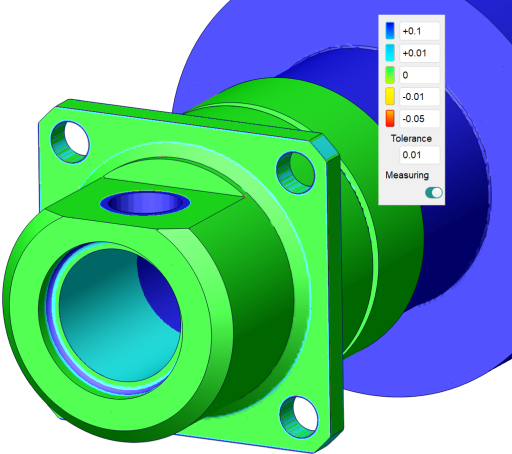

G-code simulation and transformation to other CNC formats

Interactivity

Machining result verification

Parametric CAD

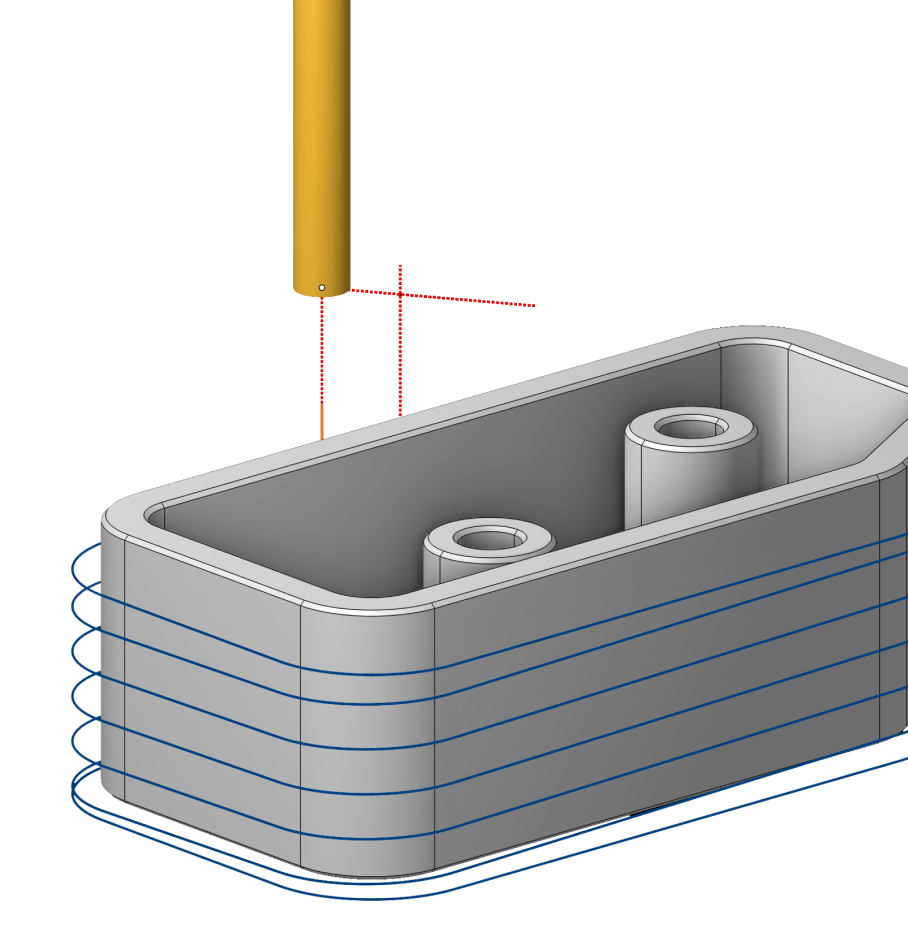

Stock-Aware Toolpath

Collision-free rapid positioning between toolpath cutting cycles

Crisp and clear interface with support of 4K display

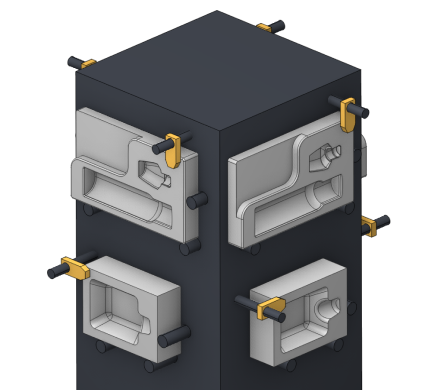

Multi-part projects supported

Snapshots

AI Assistant

Specs and Features

3-5 axis CNC machines

Supported kinematics

XYZAB

XYZAC

XYZBC

table-table

table-head

head-head

Tilted working plane (TWP)

Commands: G68.2 / cycle800 / plane spatial

2-, 2.5- and 3-axis operations

2D, 2.5D

- Pocketing

- Engraving

- 2D Contour

- 2.5D Contour

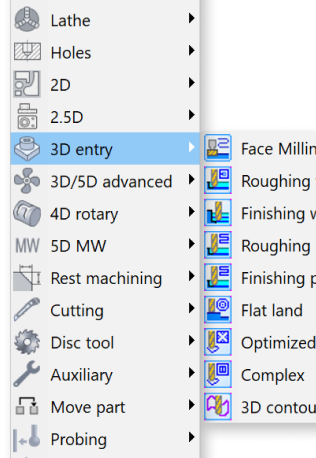

3D entry

- Face milling

- Roughing waterline

- Finishing waterline

- Roughing plane

- Finishing plane

- Flat land

- Optimized plane

- Complex

- 3D Contouring

Output format

- Corners cleanup

- Pencil

- Chamfering

3D advanced

- Scallop

- 3D Helical

- Morph

- Undercut waterline

- 5D Surfacing

Drilling cycles

- Hole machining & FBM

- Drilling cycles

- FBM Drill

- Simple drilling

- Drilling with dwell

- Chip removing

- Chip breaking

- Tapping

- Bore 5/6/7/8/9

- Thread milling

- Hole pocketing

- Tapping with chip removing

- Tapping with chip breacking

- Groove boring

FBM Drill

- Automatic hole features recognition

- FBM Procedure library

- Automatic creation of drilling operations

Hole Sorting

- Optimal

- By list

- The same plane

Output format

- Long Hand

- Canned Cycle

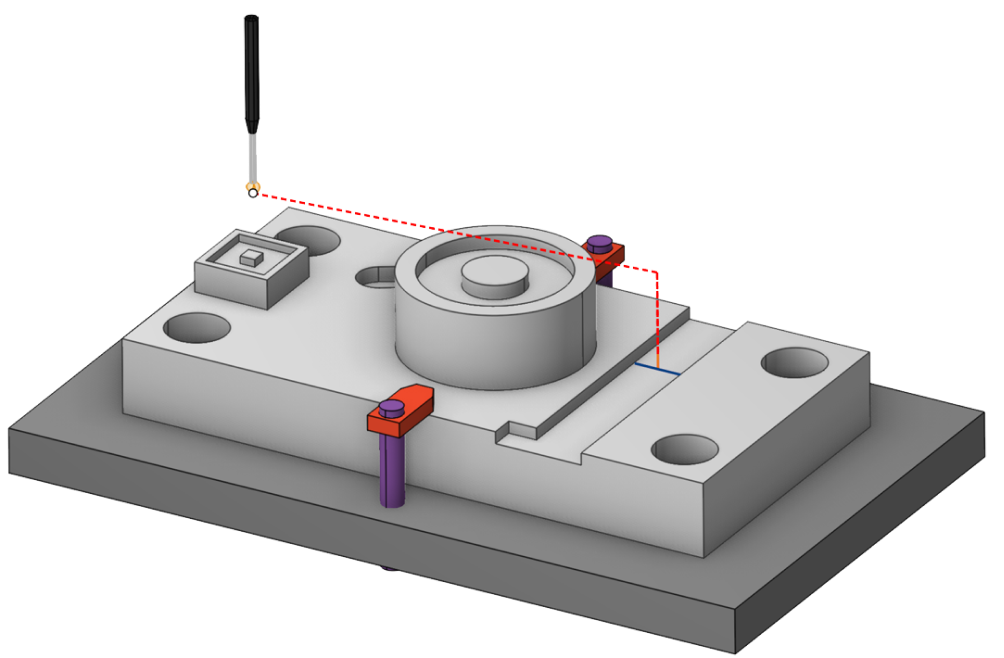

Part Probing and Tool Probing

- Surface probing

- Hole probing

- Hole protected probing

- Boss probing

- Internal rectangle probing

- Internal rectangle probing protected

- External rectangle probing

- Web probing

- Web probing (three points)

- Groove probing

- Groove probing protected

- Double wall internal corner probing

- Double wall external corner probing

- Triple wall internal corner probing

- Triple wall external corner probing

Adaptive SC

This high-speed machining cycle is specifically designed for roughing to substantially decrease cycle times and extend tool life. Its technology automatically regulates chip loads and lateral cutting forces while maintaining the cutter engagement angle and machine axes acceleration within optimal ranges.

With Adaptive SC, the machine can make deeper cuts at higher feedrates, which are also automatically optimized throughout the toolpath for maximum efficiency. In comparison to traditional machining methods, Adaptive SC provides the following benefits:

70%

reduction in cycle time

500%

increase in tool life

Technology extentions

5x Mill

Tool center point management (TCPM)

Commands: G43.4 / TRAORI / M128

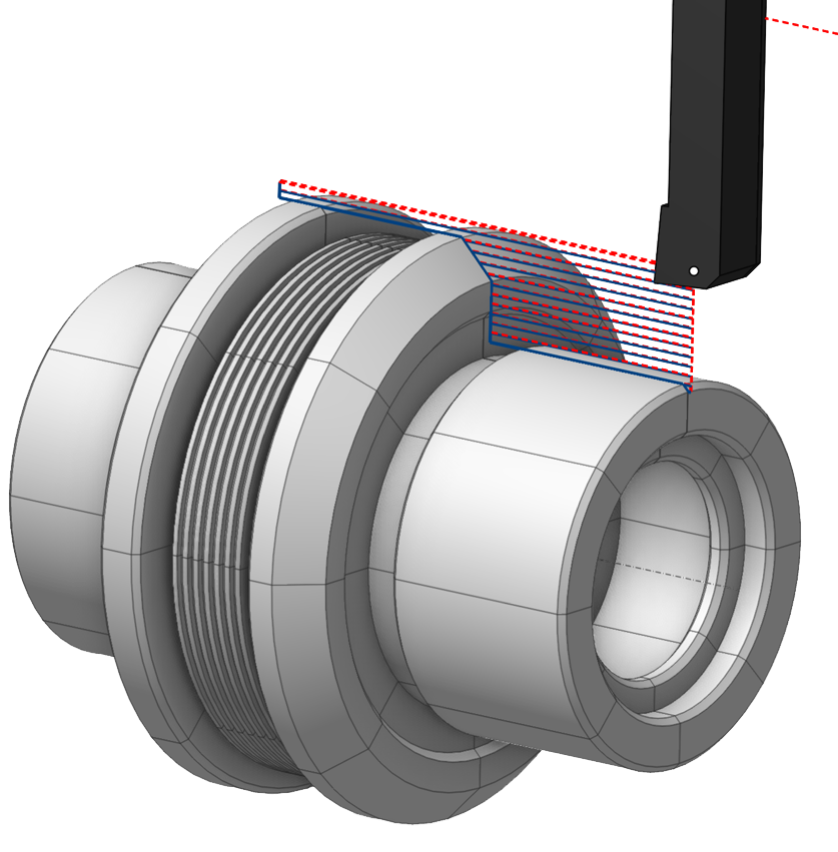

4D rotary

- Rotary waterline

- Rotary roughing

- Rotary finishing

- Morph 4D

- 4D Surfacing

- 4D Contouring

5D advanced

- 5D Surfacing

- 5D by meshes

- 6D Contouring

Turn XZCY

Advanced rough and finish profile turning, together with support for facing, grooving, threading and drilling cycles.

Lathe

- Lathe facing

- OD Roughing

- ID Roughing

- OD Finishing

- ID Finishing

- OD Grooving

- ID Grooving

- Face grooving

- OD Adaptive turning

- OD Threading

- ID Threading

- Profile threading

- Lathe part-off

Holes

- Lathe hole machining

Auxiliary

- Auxiliary operation

- G-code based lathe

Move part

- Bar feeding

Probing

- Turn tool probing

- Turn part probing

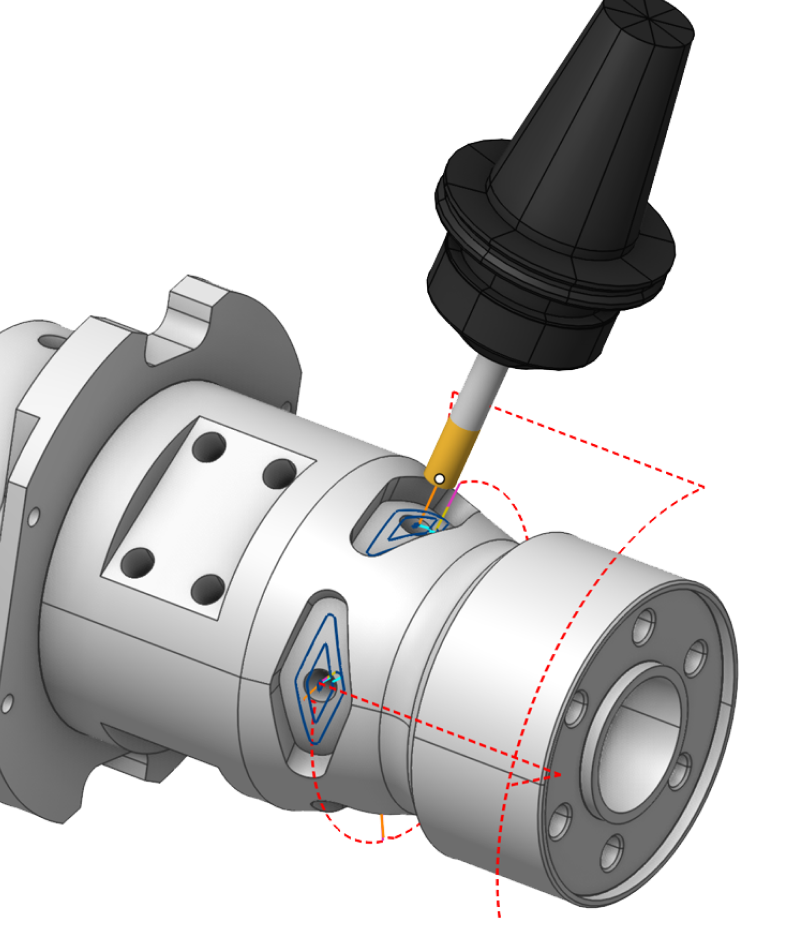

Mill-Turn machines programming

Machine-aware programming, optimization, and simulation for mill-turn machines.

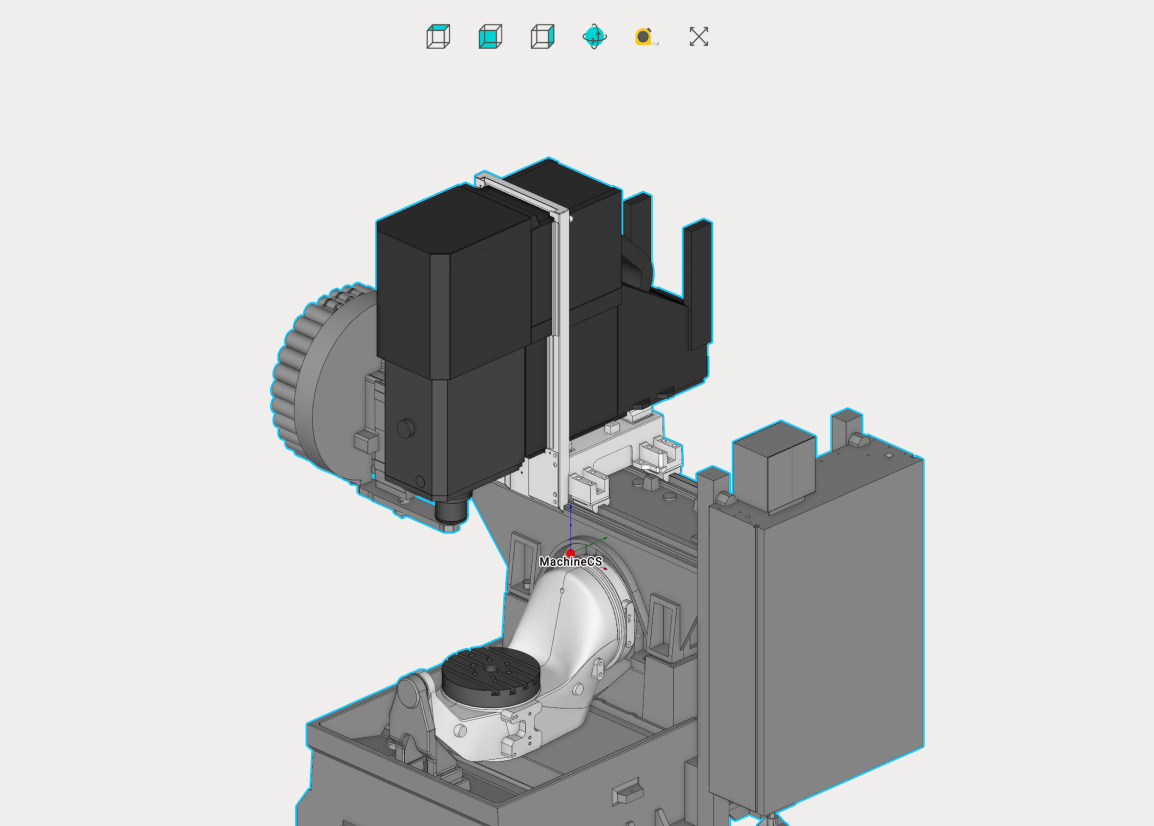

Machine-Aware Technology

- Using a digital twin for programming, optimization, and simulation

- Reduces programming time by 50% compared to a traditional workflow

Multiturret & Multichannel

- Support for multiple turrets and channels with synchronization

Synchronized Machining

- Automatic synchronization of machining operations and workpiece handling

Machining Features

- All milling and turning strategies available

- C-axis and Y-axis

- Polar interpolation

- Programming of steady rest, tailstock, bar feeder, parts catcher, workpiece loader

- Multiple spindles

- Synchronous rough turning with two cutters

Full Machine Simulation

Additive

Additive and Hybrid manufacturing enhance precision and reduce waste, revolutionizing industries like aerospace, healthcare, and automotive.

Direct Energy Deposition

- Side-by-side additive and full-spectrum subtractive programming

- Natural workflow for hybrid or dedicated additive machines

- Full simulation of both additive and subtractive operations

Meltio compatible

Additive

- Area cladding

- Curve cladding

- Cladding 3D

- Cladding 5D

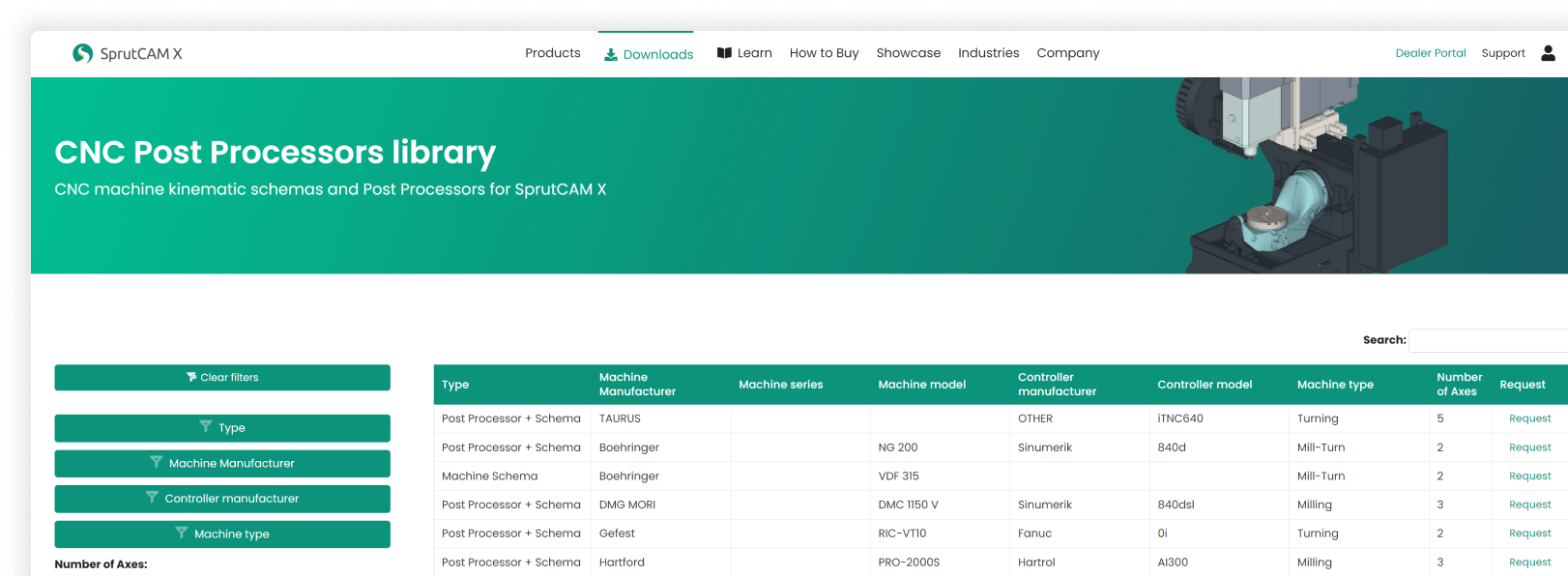

Digital twins

List of standard posts provided within installation:

- Fanuc

- Heidenhain

- Sinumerik

- Haas

Postprocessor Generator for post customization

Machine+Postprocessor from the library

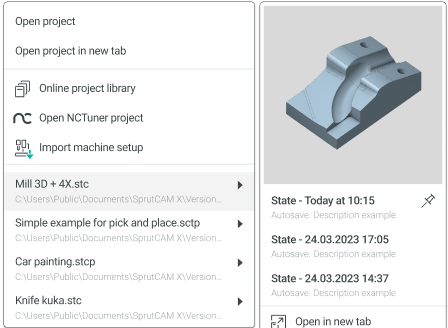

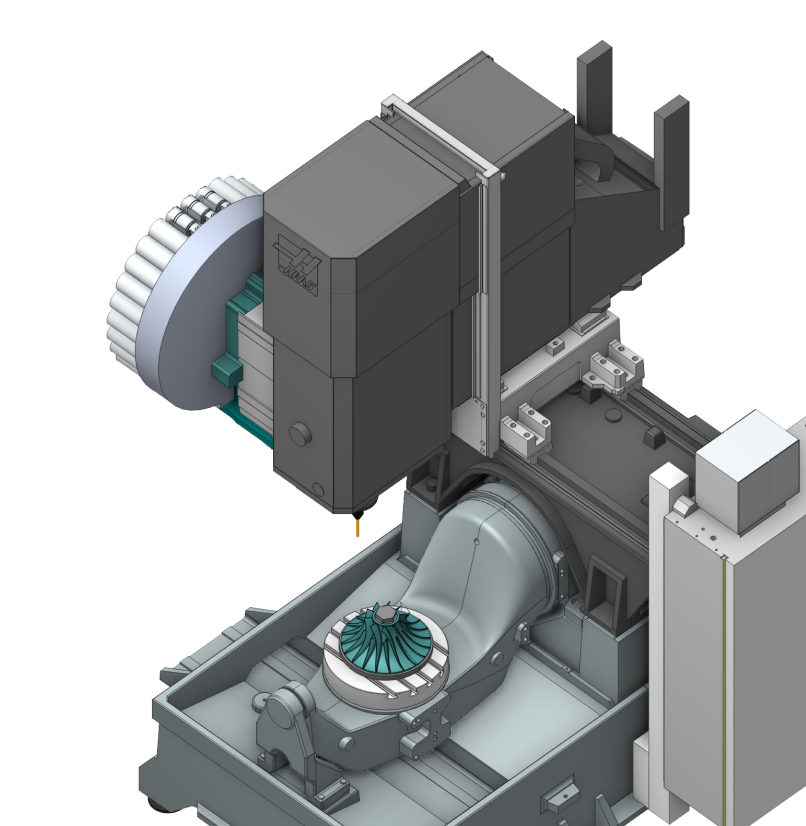

The MachineMaker app allows you to generate a digital replica of your CNC machine in a matter of minutes. This digital twin is intended for use in programming the CNC machine within the CAD/CAM software SprutCAM X.

Furthermore, MachineMaker features an extensive library of readily available individual components, as well as complete pre-designed digital twins of CNC machines and postprocessors.

#PoweredBySprutCAM

FAQ

List of CAD formats: IGES, STL, VRML, PostScript, DXF, Rhinoceros, Parasolid, STEP, SolidWorks, Solid Edge, PLY, AMF, JTOpen, PLMXML.

List of CADs with direct integration and associativity can be found at Our Partners page.

Purchase the license, get a machine twin and postprocessor

There are options. When you make a purchase you are free to choose the appropriate Digital Machine Center membership option.

Membership for one full digital machine download is included at no additional charge. For additional charge you can increase the amount of available machine twins.

In addition to that, you can build your own digital twin having 3d models and specs from the manufacturer with the zero-code digital twin builder app MachineMaker. MachineMaker is shipped within standard installation. Online documentation for MachineMaker is available at the corresponding page.

And the last option: you can order machine digital twin development and/or customization from your vendor for additional cost. Vendor information is available on the product page below the main product image/video.

There is a list of generic posts for almost any CNC control shipped with standard installation.

In addition to that there are membership options. When you make a purchase you are free to choose the appropriate Digital Machine Center membership option. Membership for one full digital machine download is included at no additional charge. For additional charge you may increase the amount of available machine twins.

Or you can develop and customize postprocessor with Postprocessor Generator app. It is included into standard installation. Online documentation is available as well as tutorial inside the app.

And the last option: you can order postprocessor development and/or customization from your vendor for additional cost. Vendor information is available on the product page below the main product image/video.

SprutCAM X naively runs on Windows. It also runs smoothly on Mac with Parallels.

System requirements are available at the trial download page.

SprutCAM X is a high-end CAD/CAM platform. Its design is centered around machine-aware toolpath calculation. However, proficiency in proper machine operation is essential. Please note that you use the software at your own risk and assume full responsibility for any potential equipment damage. Check EULA page for more information.

In essence, machine-aware toolpath calculation involves considering machine kinematics and limitations when calculating toolpaths. This ensures collision-free toolpath calculation and reliable simulation, leading to an improved user experience and significantly better time performance compared to traditional CAM workflows. This key technology places SprutCAM X in the high-end CAM category.

SprutCAM X supports a wide range of cutting tools commonly used in machining operations.

These include but are not limited to:

- End mills

- Ball mills

- Drills

- Reamers

- Taps

- Face mills

- Slotting cutters

- Chamfer mills

- Thread mills

- Bull nose mills

- Undercut mills

- Painting torch

- Welding and additive equipment

- Jet cutting tools

Additionally, SprutCAM X allows for the customization and definition of cutting tools with specific geometries and parameters to accommodate various machining requirements.