SprutCAM X Robot

Included features:

- Commercial License for robots programming and simulation

- Programming capabilities: pick-and-place, third party control programs import (ISO) and adaptation for robots

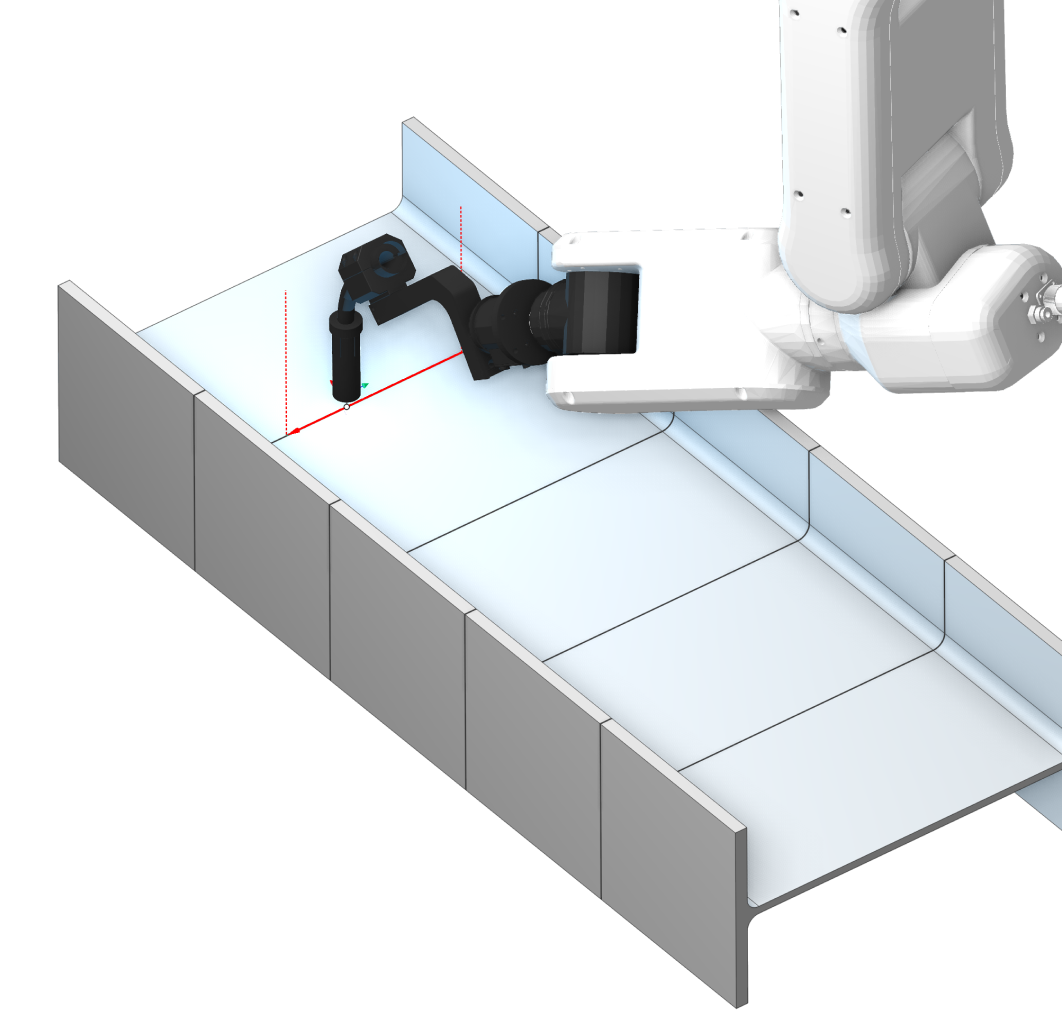

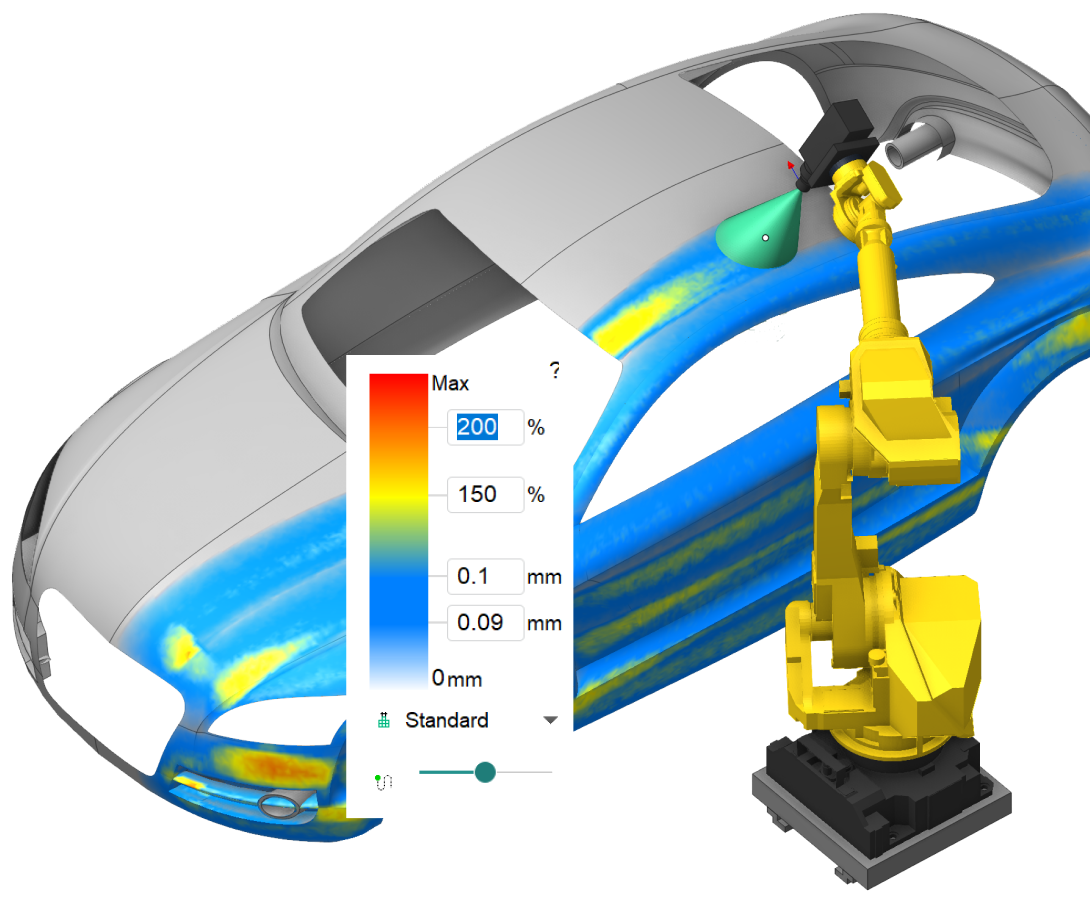

- Simulation of subtractive and additive processes

- Support for postprocessed programs verification

- Zero code digital twin builder: MachineMaker

- Generic postprocessors included

- Postprocessor generator

- Access to fundamental online video course

Options

SprutCAM X Robot Specs and Features

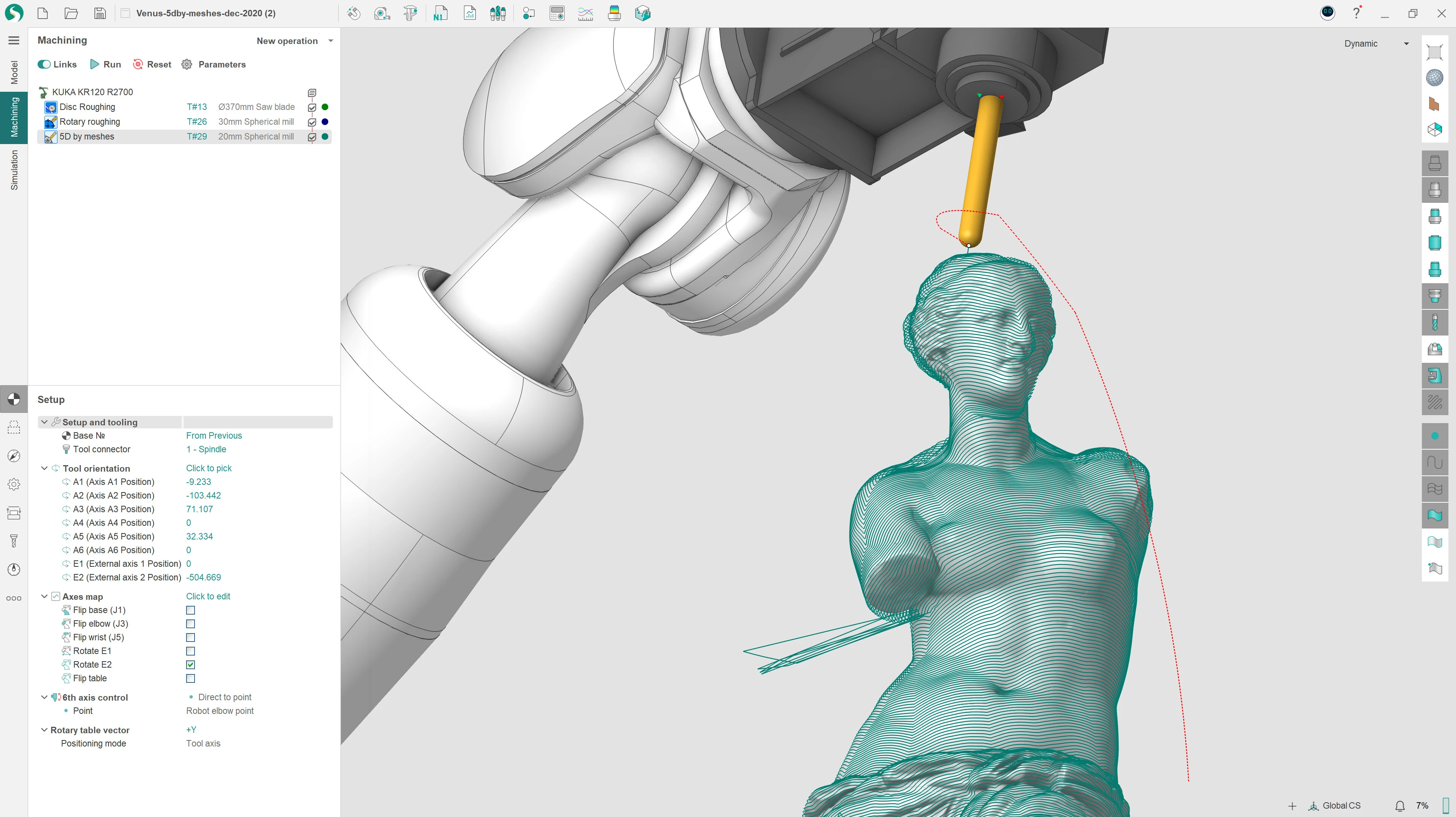

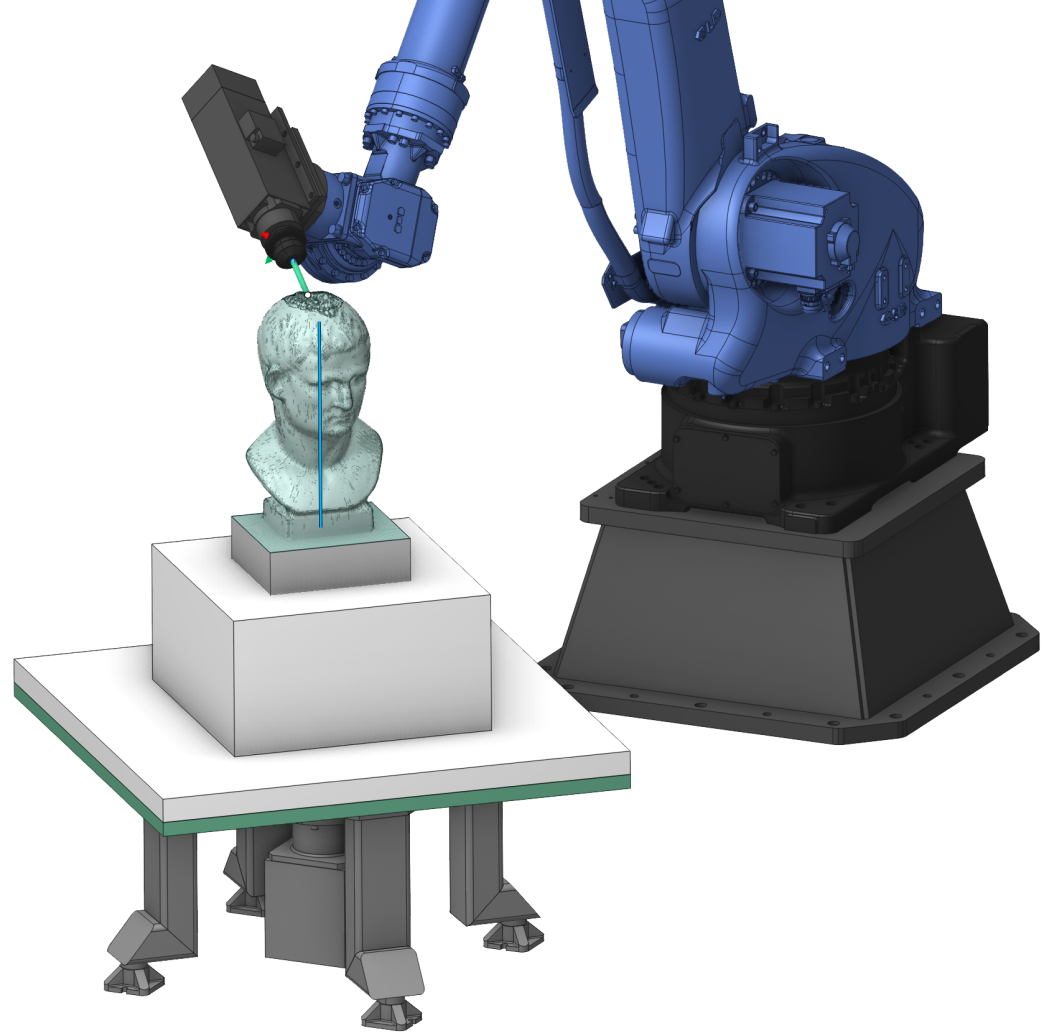

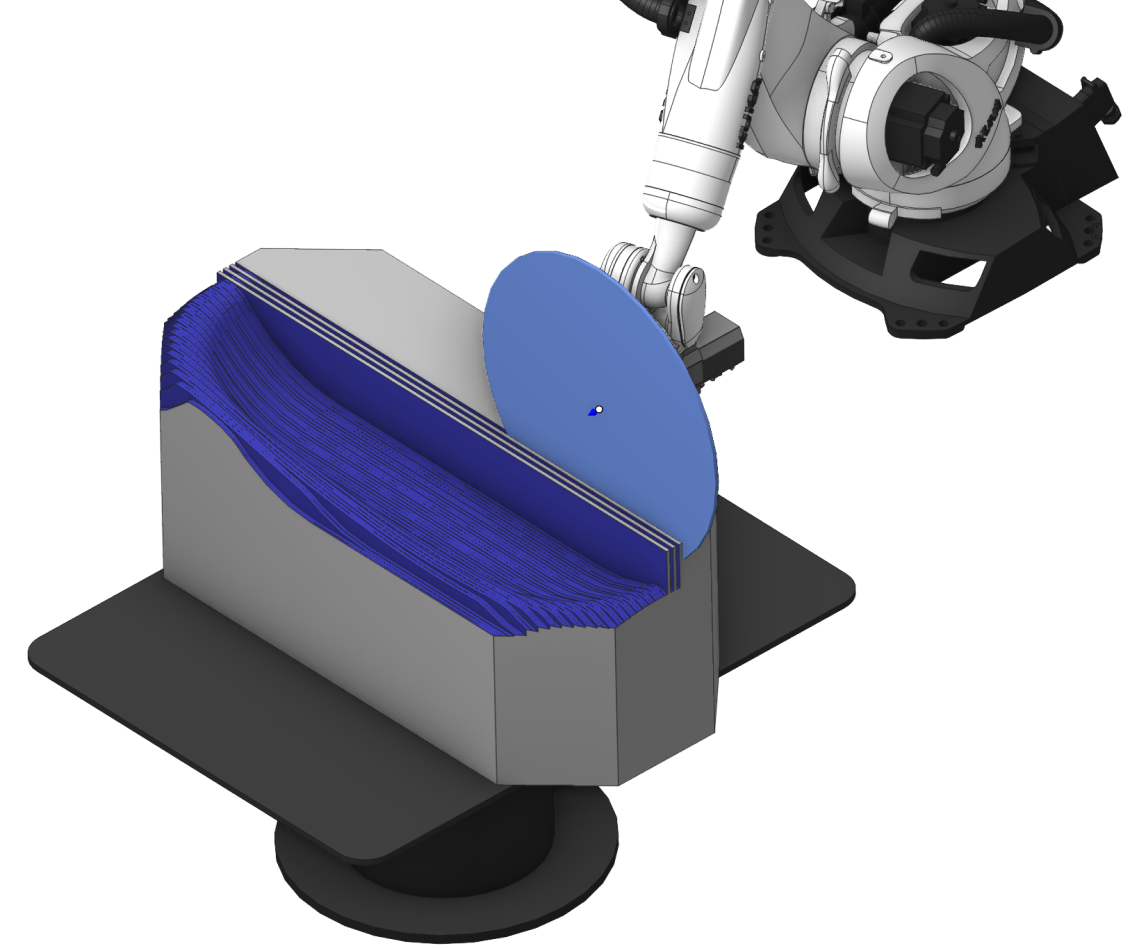

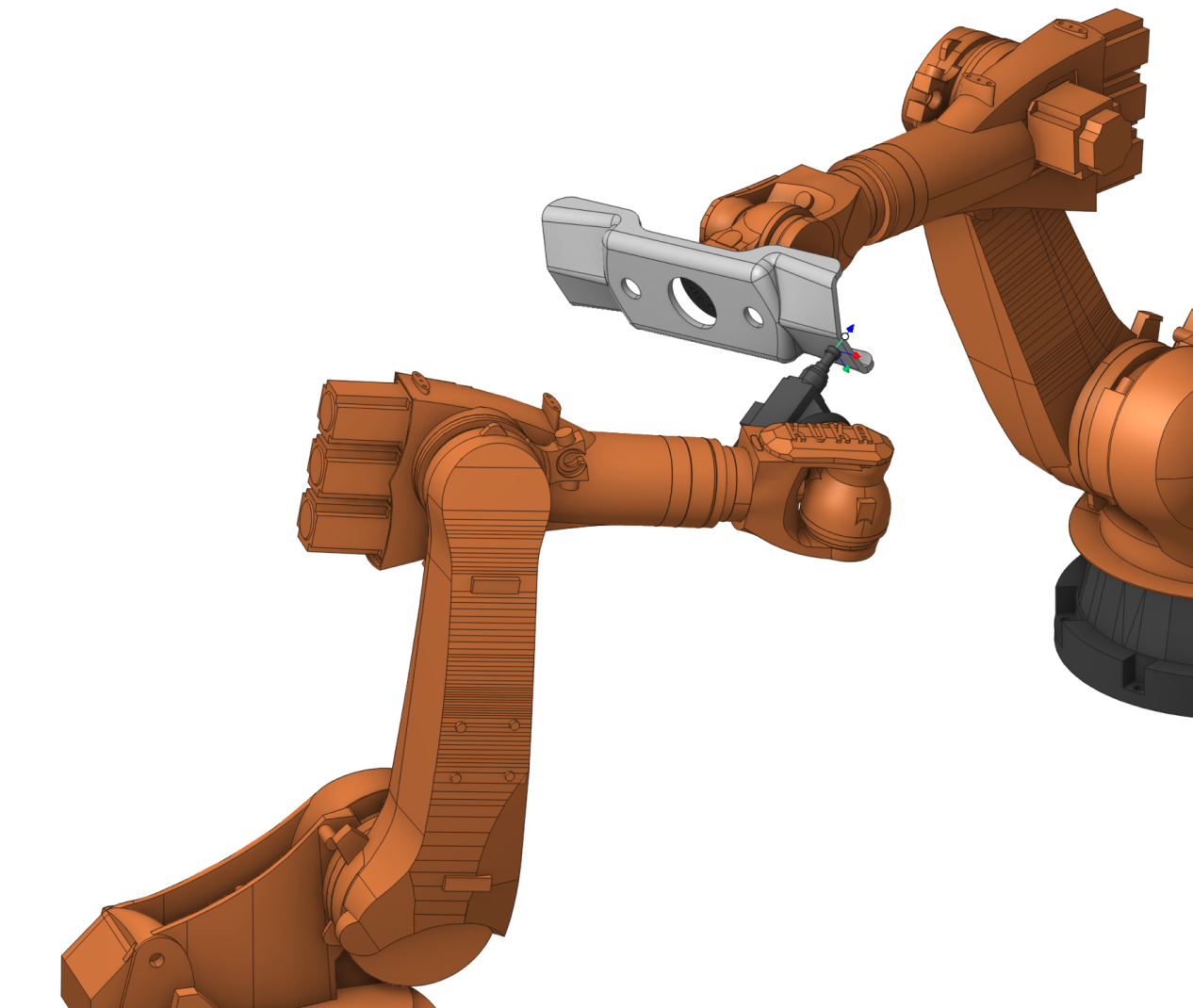

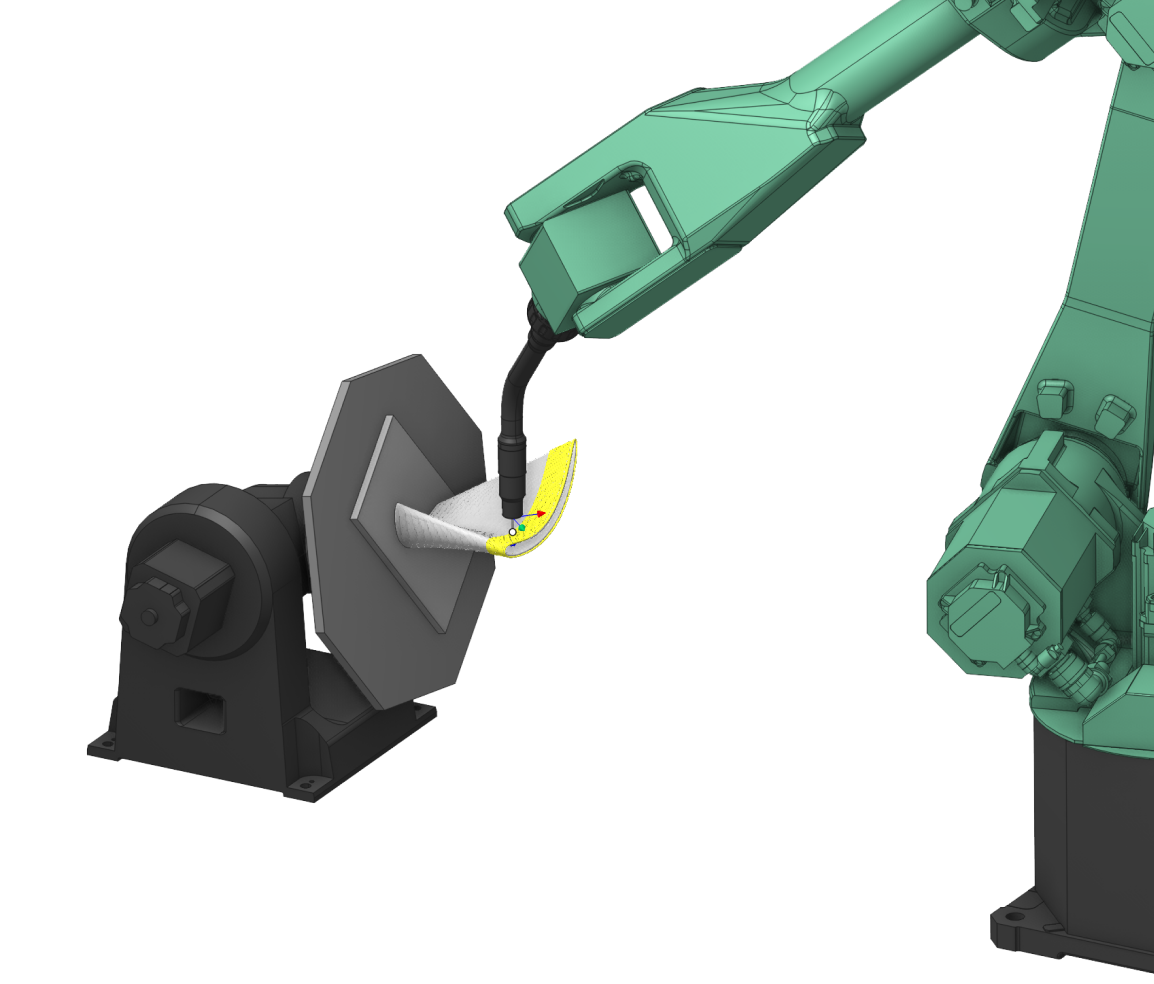

SprutCAM X Robot seamlessly integrates offline programming, simulation and code generation, delivering quick, error-free industrial robot programs. Some robotic solutions require the purchase of a separate CAM system for full operation. In the case of SprutCAM X Robot, you do not need anything else.

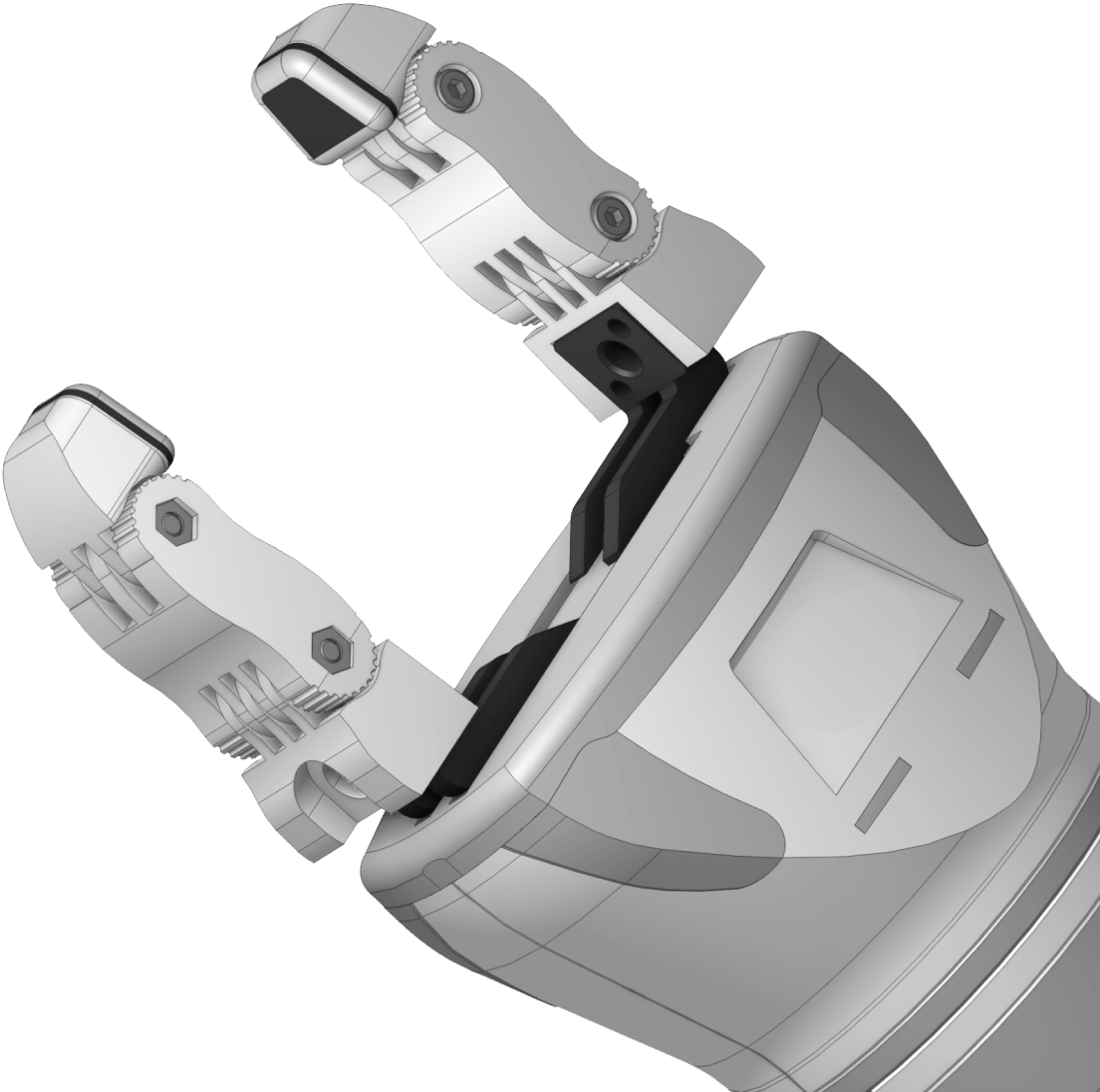

A complete solution for industrial robots

- Technology setup and toolpath calculation

- State-of-the-art simulation

- Robot kinematics optimization for singularity avoidance and collision free movements

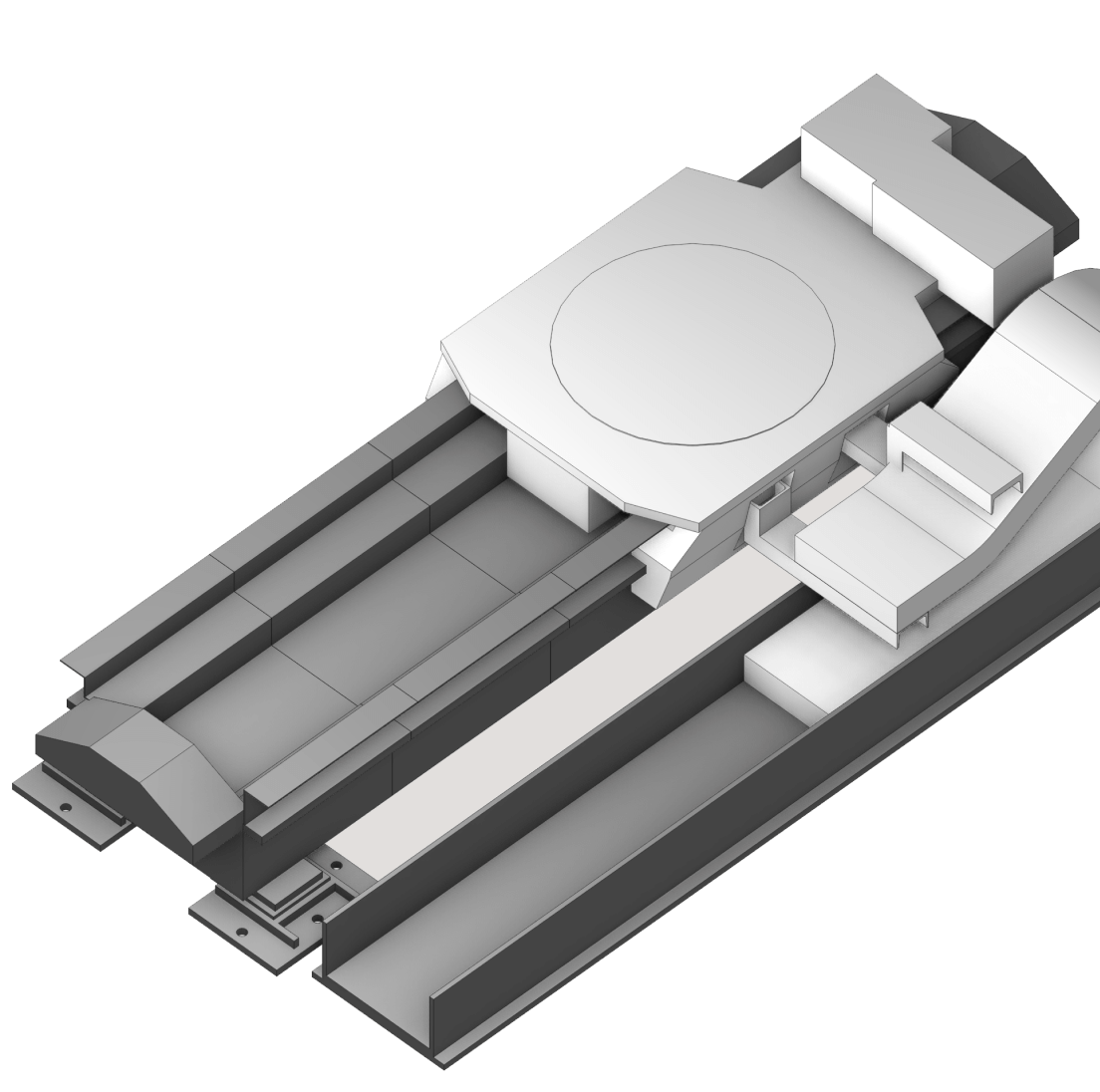

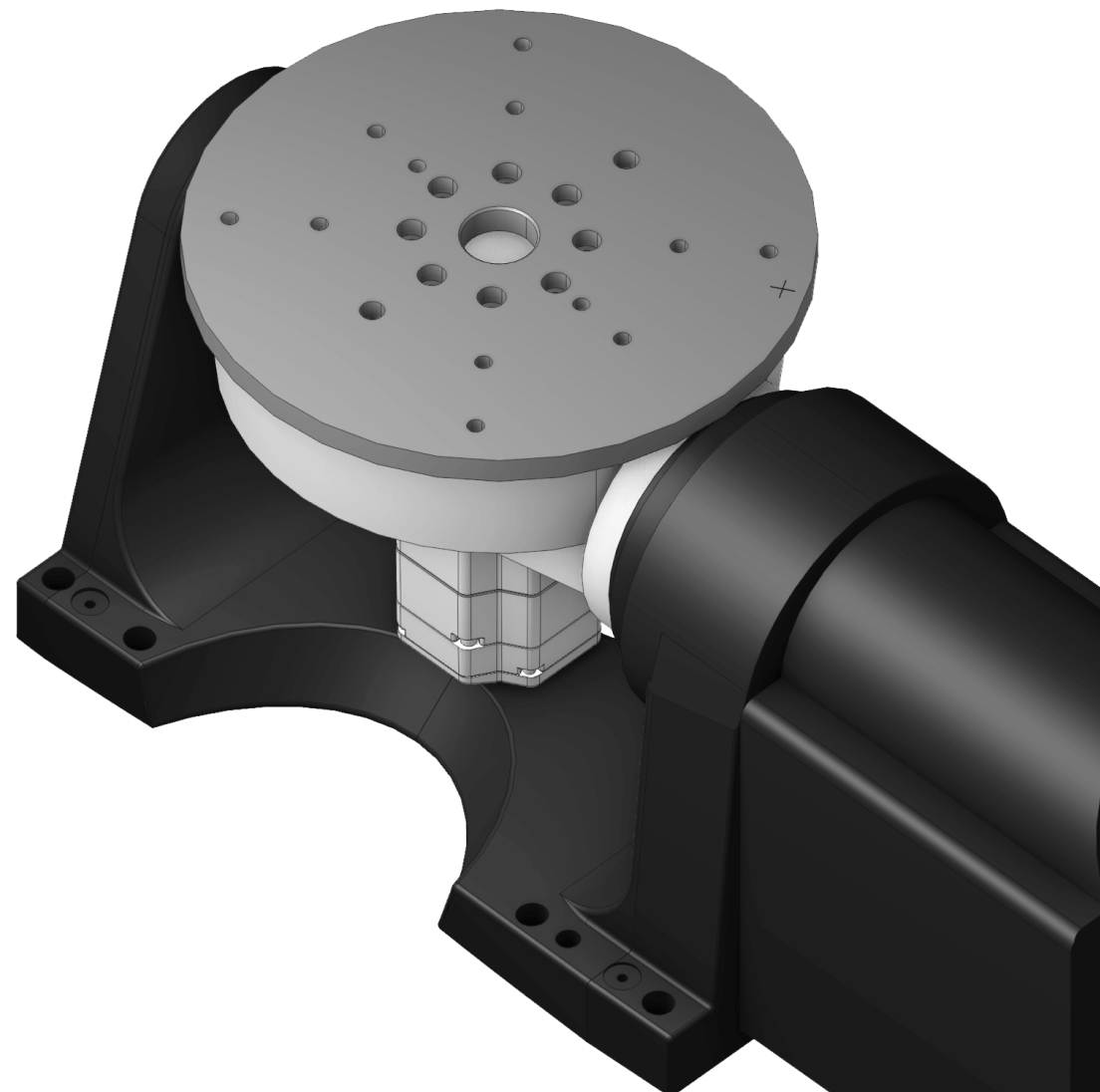

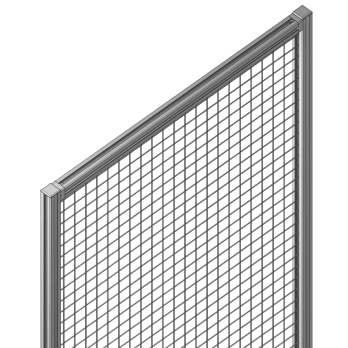

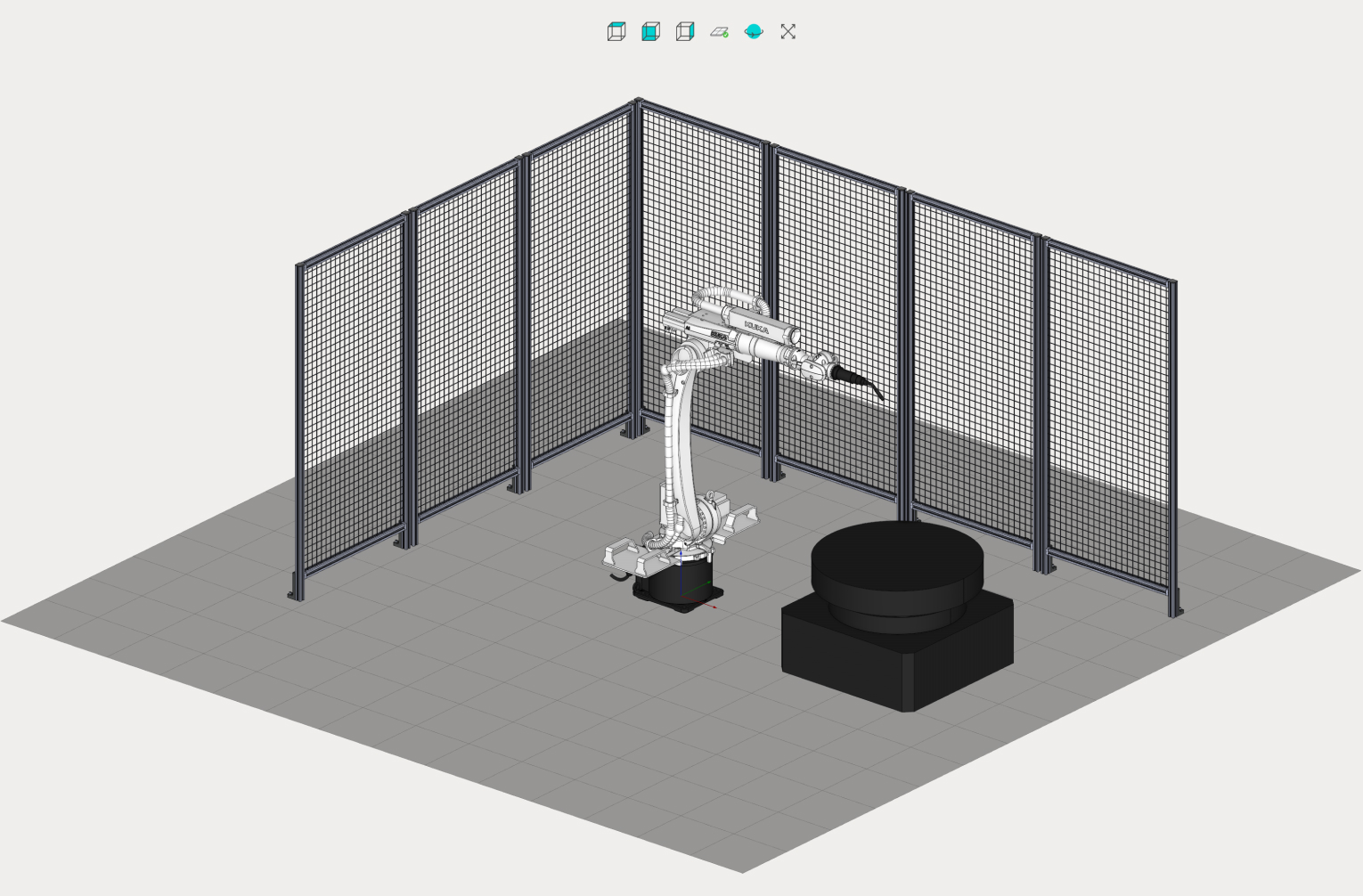

- Robotic cell zero-code digital twin builder

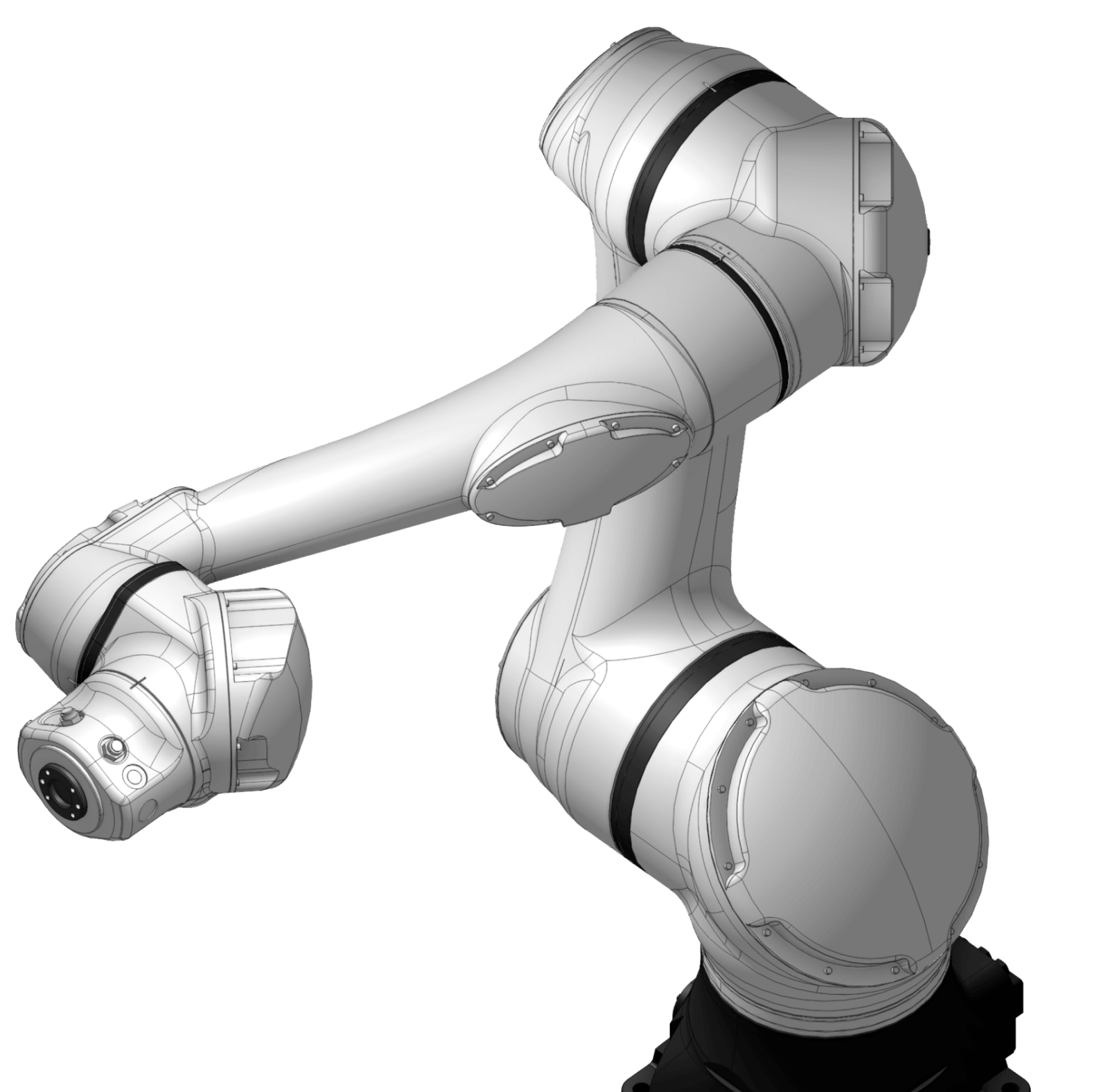

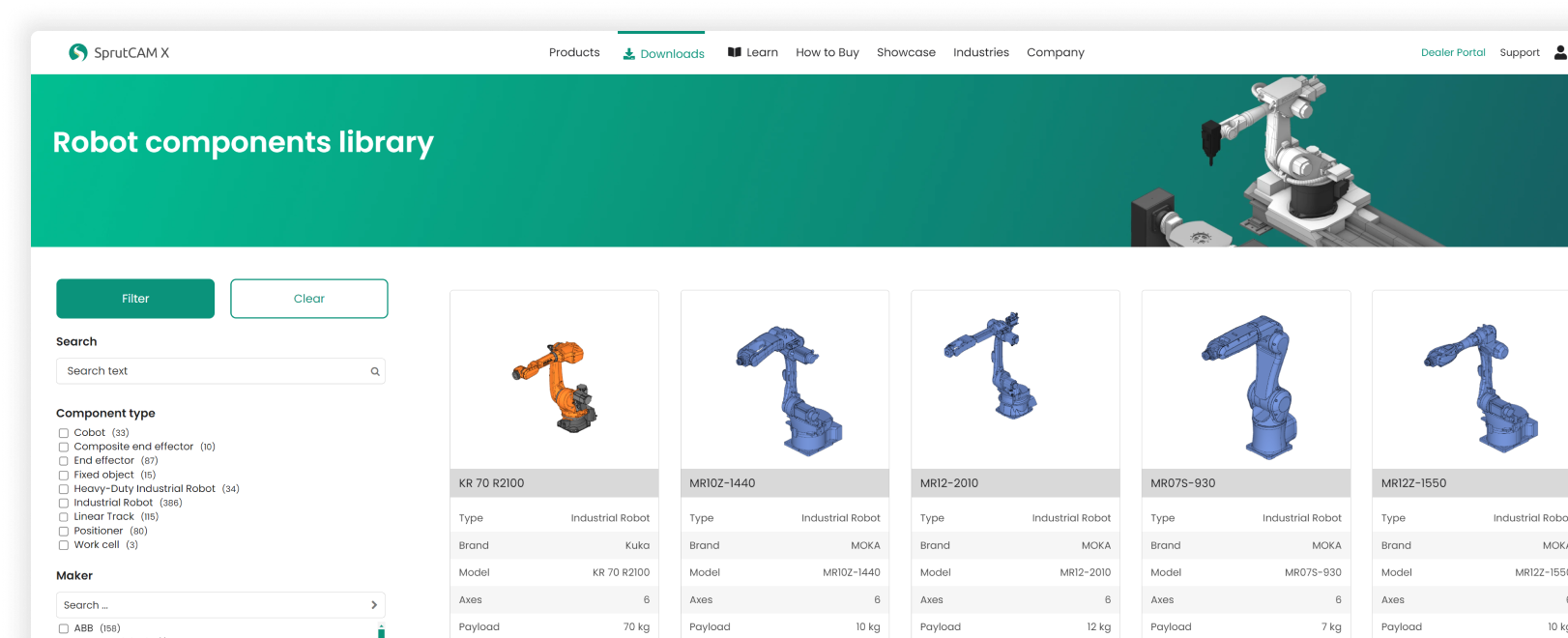

- Robot components library

- Postprocessing